50% OFF! Hot items selling fast—Grab them before they're gone!

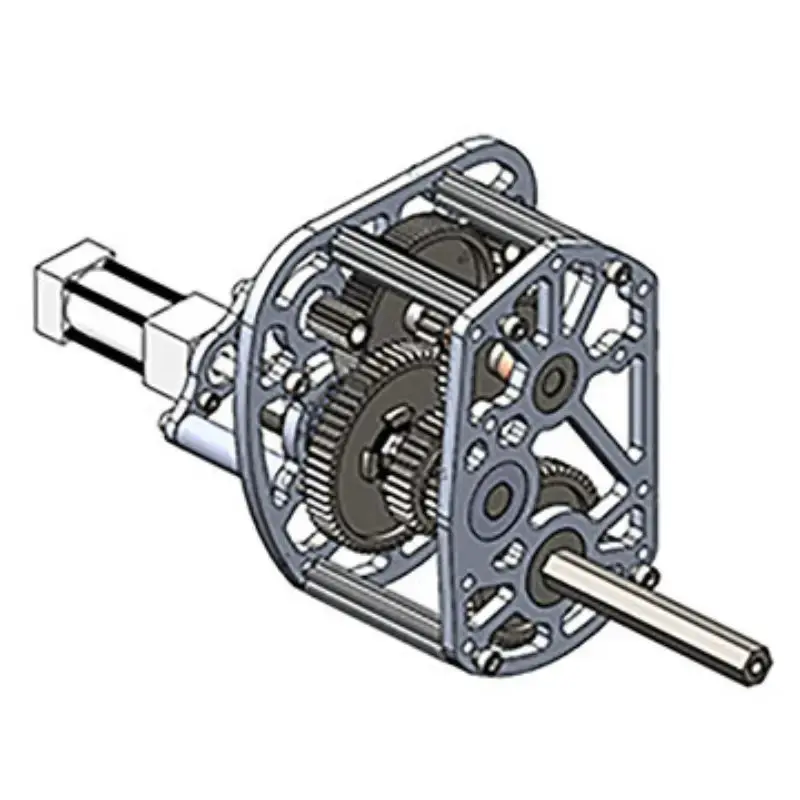

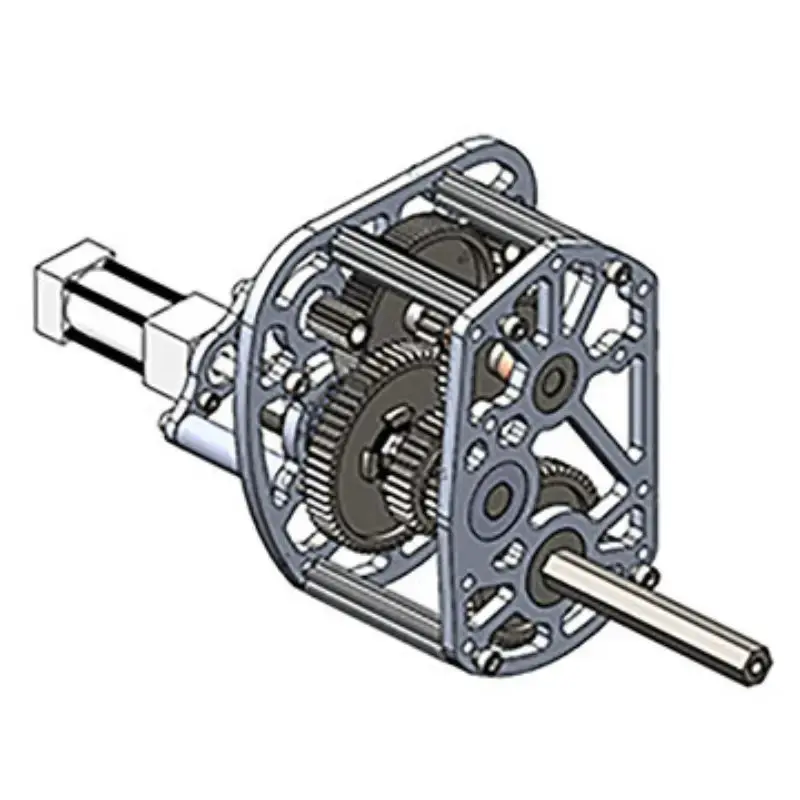

The AndyMark EVO Shifter Short Keyed Shaft, StageA 2 – 07.56:1 Ratio, StageB 2 – 22.67:1 Ratio represents a significant advancement in shifting transmission gearboxes. This two-speed, shift-on-the-fly gearbox incorporates an enhanced 4-tooth dog shifting mechanism, allowing for smooth and efficient transitions between gears. It is compatible with two CIM or NEO motors and can be configured with either two or three interior stages, offering flexibility in output shaft selection. The gearbox is delivered assembled, though motors are not pre-installed.

Several improvements distinguish this model from previous iterations. The dog gear now features four dogs on each face, enhancing strength and durability. The use of AMPCO 18 Bronze for the dog gear material provides added lubricity, facilitating smoother shifts. A robust shift block assembly with a larger bearing and threaded steel housing is included, contributing to the gearbox’s overall resilience. The input stage employs 32 DP gears and a 15-tooth pinion gear, achieving a high first stage reduction of 85:15. Users have the autonomy to select their preferred high and low ratios, with the option to swap ratios as needed.

The gearbox also supports various encoder options, including the US Digital E4T and the CTRE SRX mag encoder. Weight reduction features have been meticulously integrated into the gears and plates, ensuring a lightweight yet sturdy construction. The gearbox can be easily disassembled and reassembled without concern for gear orientation, thanks to the uniform features on both sides of the cluster gears. An optional third stage offers additional ratio choices, enhancing customization.

The EVO Shifter employs a pneumatic shift method, utilizing a spring-extend pneumatic cylinder for reliable performance during acceleration, pushing, or deceleration. This design ensures continued operation even if air pressure is lost, defaulting to Ratio A. The gearbox requires proper greasing for optimal performance and longevity, with a recommended break-in period before applying grease. Encoder programming should account for a 3:1 ratio between the output shaft and encoder shaft in two-stage versions.

View moreWhat’s Included

Specifications